Are they still making the Alpha 100?

BRANCHES of Currys, the large UK electronic box-shifter, have been displaying notices saying ‘Discontinued’ under their remaining Alpha 100 kits. This needed some explanation, so we contacted Sony UK to ask whether the camera was genuinely discontinued.

The reply is that Sony UK will not be marketing the Alpha 100 as actively after the September 6th launch of the new Alpha advanced amateur model. Stocks will continue to be available – “To confirm, A100 will be continuing until at least Christmas, however we are placing more emphasis on promoting the new model” – presumably this means they have audited the stock present on dealer shelves, looked at their own stock at home and in shipment, and worked out that it will run out at Christmas or later. Sony UK has management systems which can report all these figures. In fact, they don’t count a product successful when dealers buy stocks – they count its success or failure on the outgoing sales from the dealers to consumers.

I don’t think I am reading between the lines to suggest that the Alpha 100 is not currently in production, and has not been in production for a few weeks, maybe even months.

How can that be?

DSLRs do not come off a production line with a few hundred sensors arriving every day and the production manager ordering more for next week. DSLRs are not a ‘just in time’ component product. When the sensor – the heart of any camera – is specified and fabricated, each master has a fixed life. I do not know how many sensors a single master can make, or how many masters are made for a typical camera run. I’ve heard a figure of 10,000 mentioned as the life of a typical APS-C sensor master. The whole camera is built round the sensor.

Although CCDs and CMOS sensors are miraculously precise, each fabricating batch will be slightly different. The masters are in theory identical but there will be tiny differences in purity – literally down to molecular level – present in the silicon wafers. Every batch of materials and every new master will yield sensors which calibrate within the specified limits, but from one year to the next there’s a good chance two separate sensor runs will be significantly different. Apart from anything else, the suppliers at all stages are constantly trying to improve their products and the QC teams are trying to increase yields.

What this means is that a DSLR lifecycle is not just determined by marketing. It is also determined by the number of sensor fabrication runs, the size of the batches, and advance planning for anticipated sales. A maker may decide that 100,000 of a particular DSLR will sell in a certain period, and order all the components needed for 100,000. The CPU and image processor will be matched to the sensor’s target specifications. Firmware and calibration, once the whole system is assembled within each camera, will correct any deviation from the specification.

People have wondered why some Alpha 100 DSLRs come with firmware 1.03 and 1.04, when no ‘upgrades’ have been announced by Sony for owners of cameras with 1.00, 1.01 or 1.02 (the only official user-loadable upgrade). It may be that these later cameras all use a second fabrication run of the CCD, which differs slightly from the original launch batch run, and the firmware numbering helps engineers identify the batch. It may also fine-tune performance to match changes associated with a new sensor run.

No future in service?

What happens in the end is that no more masters remain, or are made, for a particular sensor type. The run is finite. It is not possible to produce another 1,000 cameras because no more CCDs remain and the only way to get them is to run 10,000. If you look at Nikon’s model launches based on bought-in Sony sensors, the D100, D70, D70S, D40 and D50 all used the same type of CCD. There is a rumour that the D40X (10 megapixels) was ready to go on sale but Nikon had an excess quantity of 6 megapixel sensors and the D40 was allowed some clear time to sell first. The last batches of 6 megapixel sensors may already have been made.

All the camera makers hold stocks of each sensor type and batch for repair purposes. Sony is still replacing sensors in the Minolta Dimage A1 (2004) because the original proved faulty. It is a free replacement if the 5 megapixel sensor fails (this still applies at the date of writing). They probably had to fabricate a batch of these sensors after the problem came to light, and hold them as stock to cover anticipated claims.

But one day it will be impossible to repair your 6 or 10 megapixel DSLR. No-one will be independently fabbing small batches of vintage design CCDs. When the repair reserve runs out, only cannibalised damaged cameras will be around to act as a source of parts. In this respect, DSLRs are unlike the film cameras of the past. Or are they?

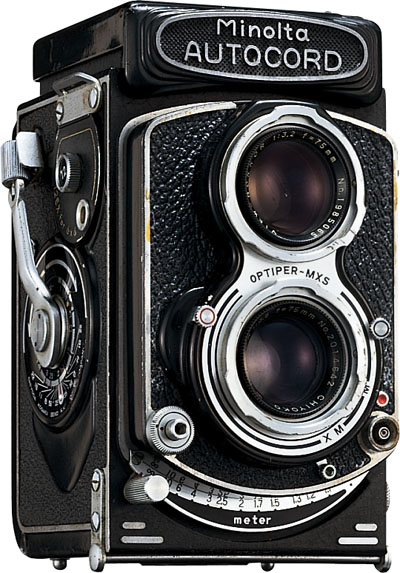

The reason that Minolta ceased to be able to repair the Autocord was that they ran out of lever-operated focusing units. This was the main cause of damage or breakdown in the Autocord. Why can they no longer repair the TTL metering on the SRT series? The last Japanese lady who formed the galvanic coils, by hand, retired. In the 1960s there were several workers, all women, who had the skill to make perfect spirals of this extremely fine wire. When diodes and LCDs took over and moving needles became outdated, no more young women were trained.

The death of today’s CCD and CMOS cameras is far more certain than the death of metering systems or focusing mechanisms. Most will cease functioning long after there is no possibility of obtaining a replacement sensor.

The switch to CMOS

Sony has announced an intention to switch from CCD sensors to CMOS, and the new Alpha advanced amateur model is the first CMOS under their own brand (apart from the Cybershot DSC R-1). The Nikon D300 appears to use a Sony CMOS sensor though as ever there is no official acknowledgment of the source.

A DSLR can not be launched until all of the first quarter’s delivery has been entirely completed and calibrated. A whole sensor fabrication batch must be measured and analysed, and the hardware design suitably matched up. All the sensor assemblies, whether in cameras or not, must be QCd. Firmware must be written suit. In the camera, final calibrations must be loaded. Each individual camera is separately set up for exposure, autofocus and sensor calibrations on a test bench connected to an automated host PC which loads settings. Those settings are unique to the individual camera body.

Then a sample of all the completed bodies must be bench tested and field tested. Some will be set up and allowed to run continuously, shooting tens of thousands of frames. Others will be used by real photographers. Before the Alpha 100 was launched, a photographer was sent out to shoot 4,000 random pictures under all kinds of conditions to ensure that everything was fine.

So, if you are looking at a September 2007 launched camera which goes on sale by October, you are not looking at something which was made the week before. The sensors were probably fabricated in early 2007 and the cameras made in the second quarter of the year. The packaging and manuals came into existence in the third quarter of the year and before shipment, every camera will have had the latest firmware loaded up after beta testing identified any problems. Even during a press launch, some cameras handed round may be late beta firmware with red stickers to identify prototype, not for sale! Meanwhile the latest firmware is being zapped into cameras ready to ship.

The last Alpha 100s were probably made in the second quarter of 2007. The entire assembly factory will have switched from one camera to the next – or a different assembly plant will have been set up, and the original one will get refitted for the third camera. Perhaps Sony is making an entry-level Alpha 100 replacement, which is not the Flagship model. Perhaps it uses the last of the 10 megapixel CCD batches. Or maybe even that will be CMOS?

‘Two cameras before the end of 2007’

Earlier this year, Sony UK confirmed to us positively that Sony would launch two new DSLRs before the end of the 2007 calendar year. We even questioned whether they meant the financial year, by March 2008. No, came the reply. We mean 2007. This year.

Will the second launch of 2007 be the flagship?

I don’t think so. I think the Alpha 100 is marked as discontinued, and in short supply worldwide, because Alpha 100 assembly came to the end of the last run of components. Spares will have been set aside for future servicing, and the Alpha 100 closed as an active project. Sony could not afford to have no entry-level DSLR, though the Alpha 100 has been entry-level in price terms only. It has been a viable professional tool, let alone a good enthusiast’s camera.

What will they have?

I’m pretty sure the second DSLR launch of 2007 will be the replacement for the Alpha 100, probably with no great external changes. If, like us, you want a second Alpha 100 body or just fancy picking up an Alpha 100 at the currently very good prices, don’t wait. This is not your camera purchase. This is the money you would have spent on film and processing. We sold a Konica Minolta 5D and bought an A100 to replace it as our second camera. The difference between the selling price and the new camera was about £150. The 5D had just under two years of use.

As new DSLRs are launched, keep up to date. Sell and buy your DSLRs without any of the hesitation you might once have felt about upgrading to each new film SLR. The advances with each generation are worth it, and keeping old DSLRs for a very long time will one day mean you may have a camera which can not be repaired and is worth nothing.

In the meantime if you want an Alpha 100, buy soon!

– David Kilpatrick

Fascinating stuff – thanks for another great article.

btw do you know that http://www.iconpublications.com will not load?