Smoke and Mirrors – an idea for Sony

With the latest Alpha 77, Sony has introduced SLT version II, the new upgraded ‘Translucent’ mirror. This is in an attempt to reduce the ghosting effects created by having an angled mirror between the lens and sensor, the image forming rays passing through a semi-silvered (pellicle) surface, through a thickness of polymer film, and then to the sensor. Having tried it out (update, September 8th) we can confirm that it works. You honestly would never know there was anything between the lens and the sensor.

But Sony, like all makers, has continued to think in terms of SLR design and the old world of film negatives and slides, where the image always had to be a certain way up on the film, or it would end up being printed and projected reversed left to right.

In the past a simple reflex mirror for a TLR viewing screen – like the Rolleiflex – did a useful job of turning an inverted image the right way up for viewing. On film at the back of the camera, the image was both inverted and left-to-right. But that did not matter, as the film was viewed through its reverse (back) side to see or print the image.

Somehow, this old design has been continued to new cameras – but today we use digital sensors. The upside-down or left-to-rightness of the image does not matter as we view the image on a screen or using an EVF. No matter how the image ends up on the sensor, it can always be the right way up and the right way round for us to view.

So, Sony, when you make you that full-frame Alpha 99 camera change the entire approach. Position the SLT mirror so it reflects the image sideways, upways or downways! And put the SENSOR where it receives the image from the REFLECTED lightpath. Make the mirror reflect 70% of the light and transmit 30%, instead of the other way round.

There will be no double imaging, no flare patches, no ghosting and not even an extra substrate or layer for the image forming rays to pass through, if the sensor receives the reflected image not the transmitted one. The AF sensor, in the meantime, can be positioned in direct line to the lens where the imaging sensor has been in the past, measuring the image through the SLT mirror.

This arrangement (©David Kilpatrick, Friday morning, August 26th 2011, scrambled eggs with smoked salmon for breakfast) will in a single stroke remove all the complaints about image degradation as the mirror will provide a perfect image.

But – would it? Slight lack of plane perfection in the SLT mirror used to transmit the image-forming light, and reflect the AF-measuring light, does not have much effect on the image. Anything less than an optically perfect mirror would fail to create a quality image. It would be like sticking a cheap filter on your lens, or worse. And of course it would never fit into a normally shaped camera body with a full frame sensor and shutter.

Solid solution

Ah – the AF sensor, unlike the imaging sensor, does not need cleaning to remove dust spots. So the mirror would not have to be movable. Actually, it would not have to be a pellicle mirror. It could be a lovely big lump of pure glass prism moulded straight on to the AF module itself, even including the condensor-collimator lenses of the AF system. It could be solid glass all the way from mirror surface to AF receptor, and the 45° front face could be to the same optical perfection as the best Sony G lens. Or even the best Carl Zeiss lens. Hell, it could be a Carl Zeiss prism and then the camera could have the CZ logo!

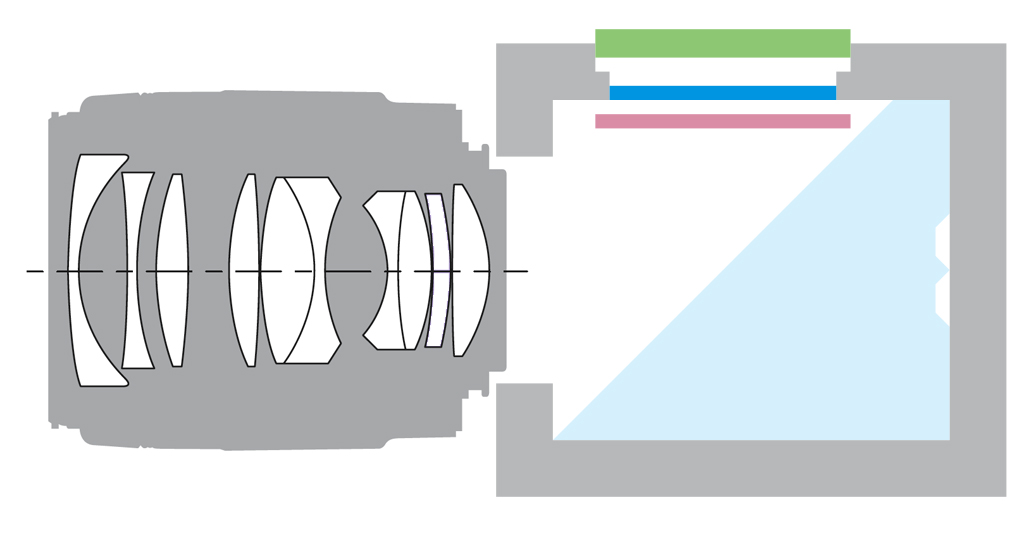

Diagram above: light blue = solid glass optical prism with 45 degree semisilvered front face; the two white indents at the right hand side indicate AF modules set into the prism rear face. Pink = shutter (optional, ideal system would have electronic shutter only). Dark blue = sensor. Green = top mounted waist level viewing screen, also articulated. A secondary eye-level EVF would or could be used. Design ©DK with a bit of nicked Sony lens cross-section.

Design? Rollei 6000 all the way! A professional, Hasselbox-shaped thingy to cradle in your hand. With a rotating 24 x 36mm sensor too, so that you change the format aspect by pressing a button not maneouvring the camera body. A 3 inch square OLED on the top like a giant waist-level finder, showing the image vertically or horizontally as you turn the sensor. A waist-level viewing hood for a giant magnified view. Maybe even a monster top prism for the biggest EVF you could imagine!

Mor realistically, an eye-level EVF in addition to a top plate OLED or LCD panel designed to be hinged up/rotated/twisted – rather like the LCD of the Sony Cyber-Shot DCS R-1, one of the best ever ‘waist level finder’ options fitted to a digital camera to date. In fact something like s giant updated R-1 full framer might do well.

As for the image sensor, that could be in the well of the camera (mirror aiming down) but maybe having it in the top of the camera, below the viewing screen (mirror facing up) would help gravity reduce the dust issue.

The point is – it does not matter where the image sensor is placed, it does not have be where the film once was. It does not matter whether the image reaching it is inverted or reflected, as unlike film it does not have an emulsion side or a film-base side, the electronic viewfinder is independent of the orientation of the optical image.

Future ‘SLT’ EVF cameras – especially a future Alpha 900 replacement – do not need even to resemble today’s DSLRs and can be made better by abandoning ideas fixed in designers’ minds since the era of film cameras.

– DK

Technical note: angled partial mirrors, whether prism surface or semi silvered, create polarisation effects, colour shifts and a varying efficiency of reflection depending on the angle of incidence of the ray. This is one barrier to the use of pellicle mirror design for a full-frame model, as the back focus or telecentricity of lenses relative to the format would mean a greater range of incident angles across the mirror surface. Sony appears to have overcome any such problems in the existing APS-C SLT design, and the slightly forward tilt of the mirror (not a true 45°) helps in this respect. I propose the above design in full awareness of related optical and technical issues. I’m not assuming they do not exist – they would need solving.